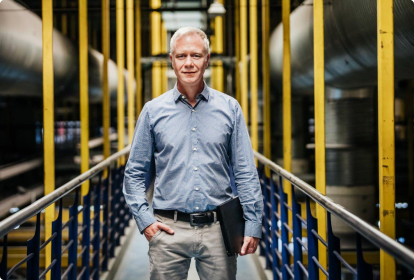

To support and guide businesses on their journey to achieve industry best practices in machine and process safety.

We believe in a one-team approach, bringing together experts in all the necessary disciplines to ensure practicality, compliance, and the most accurate systems and processes tailored to your unique requirements.

As your expert partner, you can be confident that your safety needs are met with precision and your business goals in mind.

To revolutionise machine safety with seamless, end-to-end solutions that ensure the highest safety and compliance standards. We strive to be the industry's leading innovators, providing everything from initial assessments and consultations to complete project execution.

Our goal is to eliminate the complexities and inefficiencies of managing multiple contractors by offering a single point of contact for all your machine safety needs.

We are committed to excellence and customer satisfaction, we aim to safeguard lives, protect assets, and enhance operational efficiency for every client we serve.

Our directors identified a significant gap in the machine safety industry: no single provider was offering a complete, end-to-end safety solution.

Businesses would receive Requirement Specifications but then had to navigate the rest of the process on their own. Navigating the rest of the process alone is not ideal because it leaves businesses vulnerable to potential oversights and compliance issues. This fragmented approach can also result in inconsistent safety practices, inefficiencies, and additional expenses.

Identify hazards and quantify associated risks. Assign corrective measures and determine required Performance Levels.

Based on the information from the Risk Assessment, this section details the functional requirements necessary to mitigate risks to a negligible level. It also specifies the required overall safety rating of the system.

Utilising information from the Safety Functional Requirements document, the system is designed and verified to ensure that the achieved Performance Level meets the required PLr (Performance Level Required).

The system is installed, and each safety function is validated to ensure proper installation and correct functionality.

Ongoing maintenance and continuous improvement.