Machine Safety Australia recognises the critical importance of creating a secure operational environment. Our expertise is grounded on AS /NZS 4024.1 2019, Safety of machinery standards, a guideline designed to achieve the highest machine safety levels throughout a machine’s lifecycle. These standards offer a systematic approach to hazard management, focusing on identifying, assessing, and controlling risks to ensure proper machine safety.

Implementing the principles of machine safety is more than a practice for MSA—it’s a commitment to safeguarding your workforce and enhancing operational efficiency. We integrate proper machine safety concept into the very core of your machine operations, ensuring that it becomes a seamless part of your process. Our safety solutions and expert insights will guide you in establishing a safer, more productive workplace.

We have fully embraced the AS /NZS 4024.1 2019, Safety of machinery standards as the foundation of MSA machine safety concepts. These standards include the fundamental safety concepts that are essential for the lifecycle of any machine. By incorporating these standards into every aspect of our services, we ensure that your machinery meets the highest safety benchmarks from design through operation and maintenance.

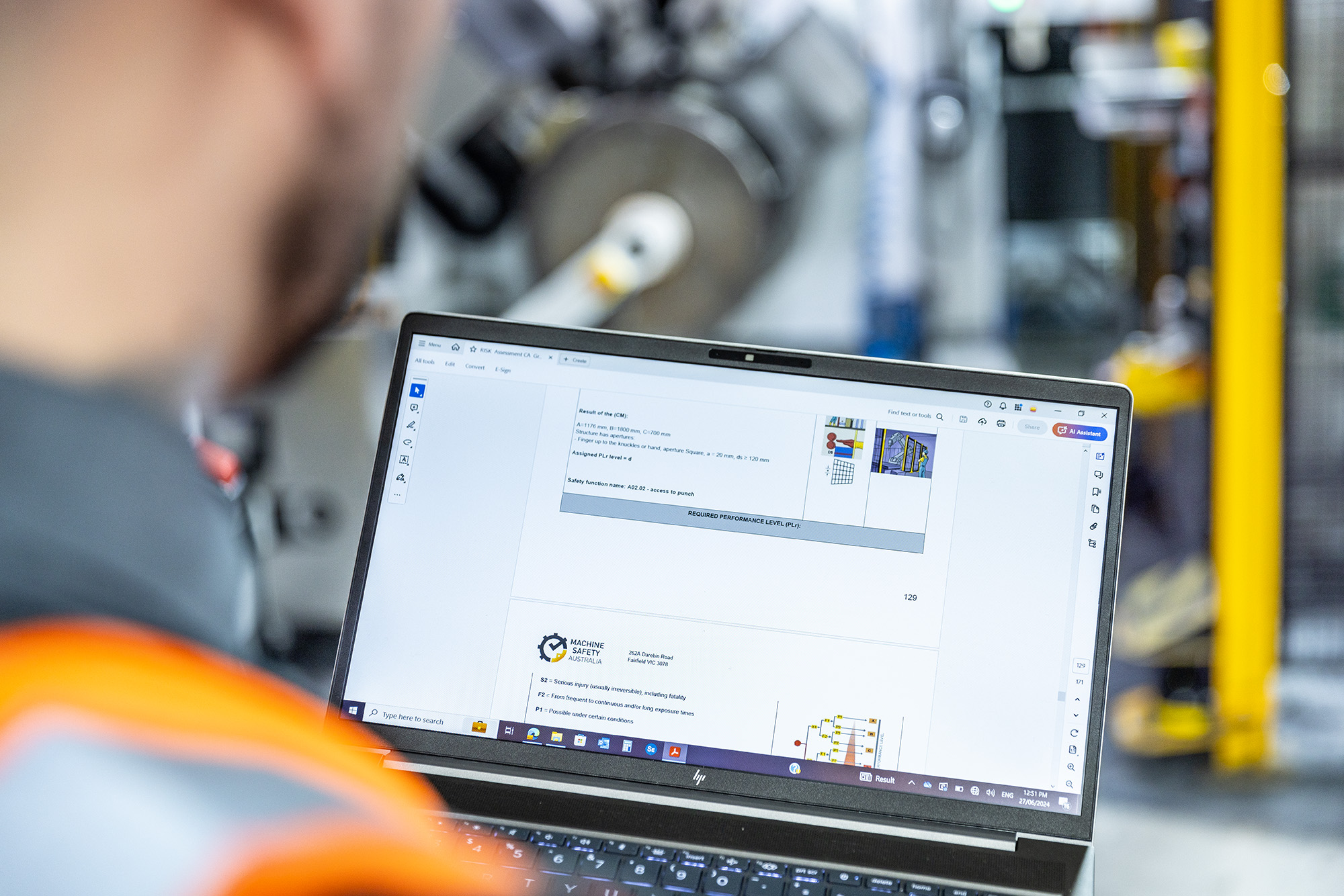

This integration begins with our detailed risk assessments on your machines, where we identify potential hazards and evaluate existing control measures based on machine safety standards. From there, we develop customised machine safety concepts tailored to your specific needs, ensuring that all safety-related parts of control systems meet the required machine performance levels.

MSA's top priority in safety strategy is to eliminate hazards entirely. By removing the source of danger, we ensure that the risk is minimised to the greatest extent possible. This could involve redesigning machinery, modifying processes, or removing hazardous substances altogether.

When eliminating hazard is not feasible, the next step is substitution. This involves us replacing hazardous materials or processes we might encounter with less dangerous alternatives.

We provide engineering controls through physical modifications to your machinery or the workplace to reduce exposure to hazards. This could include installing guards, barriers, or ventilation systems. By implementing these controls, we can isolate people from hazards and reduce the likelihood of injury.

Changing the way people work is another effective strategy of MSA for managing risks. Our administrative controls involve creating and enforcing procedures, training programs, and work schedules that minimise your exposure to hazards.

As the last line of machine safety control, we provides guidelines on selecting and using the appropriate protective gear for protecting workers when other controls are not sufficient.

With AS /NZS 4024.1 2019, Safety of machinery standards emphasizing the importance of designing machinery with inherent safety features and controls. Machine Safety Australia safeguards and interlocks all machine mechanisms to prevent access to hazardous areas and minimise risk during work operations.

An integral part of our machine safety concepts is ensuring that safety functions are appropriately designed, validated, and maintained. Safety-related parts of control systems are important for achieving the required machine performance levels. We have this system designed to detect and respond to faults in a way that does not compromise machine safety in your workplace.

Safety is an ongoing process, and MSA is committed to continuous improvement. We regularly review and update our machine safety concept to reflect the latest advancements in technology and best practices. By staying up to date with the industry standards and innovations, we ensure that your machinery remains safe and compliant.

Achieve the highest machine safety standards for your workplace with Machine Safety Australia. Learn our Machine Safety Concepts to guide you through the necessary safety principles to safeguard your employee.