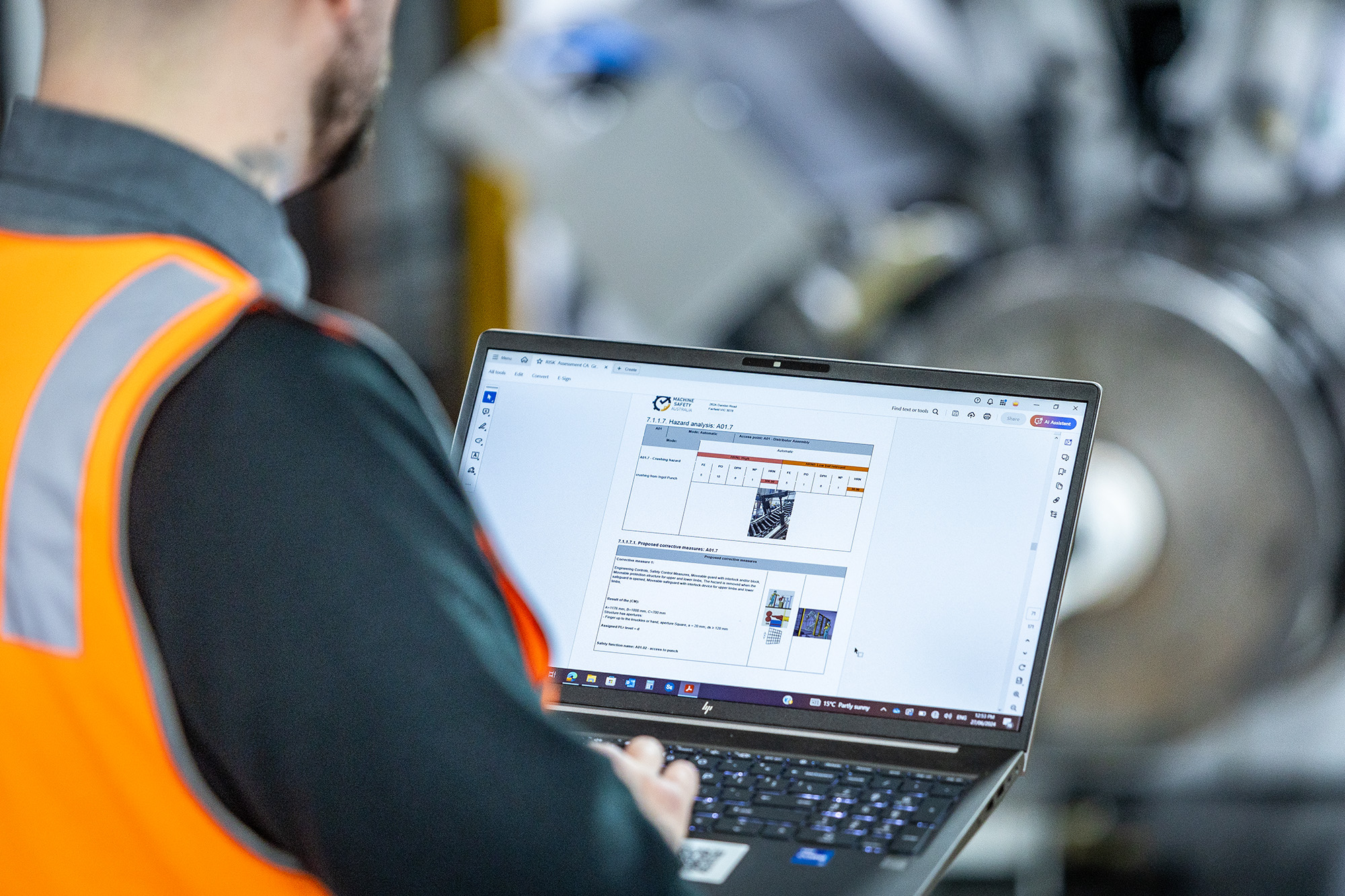

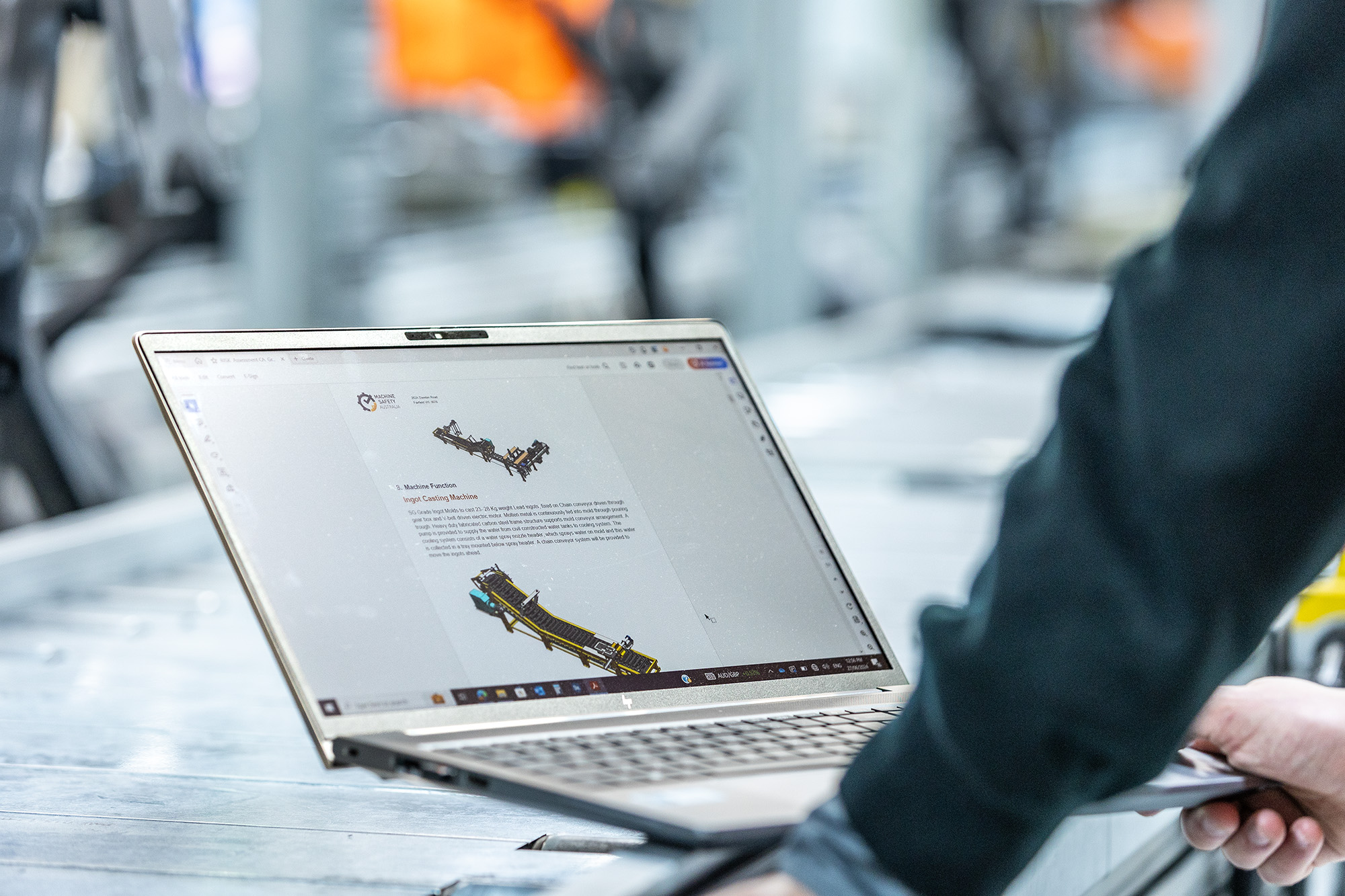

Identify hazards and quantify associated risks. Assign corrective measures and determine required Performance Levels.

Based on the information from the Risk Assessment, this section details the functional requirements necessary to mitigate risks to a negligible level. It also specifies the required overall safety rating of the system.

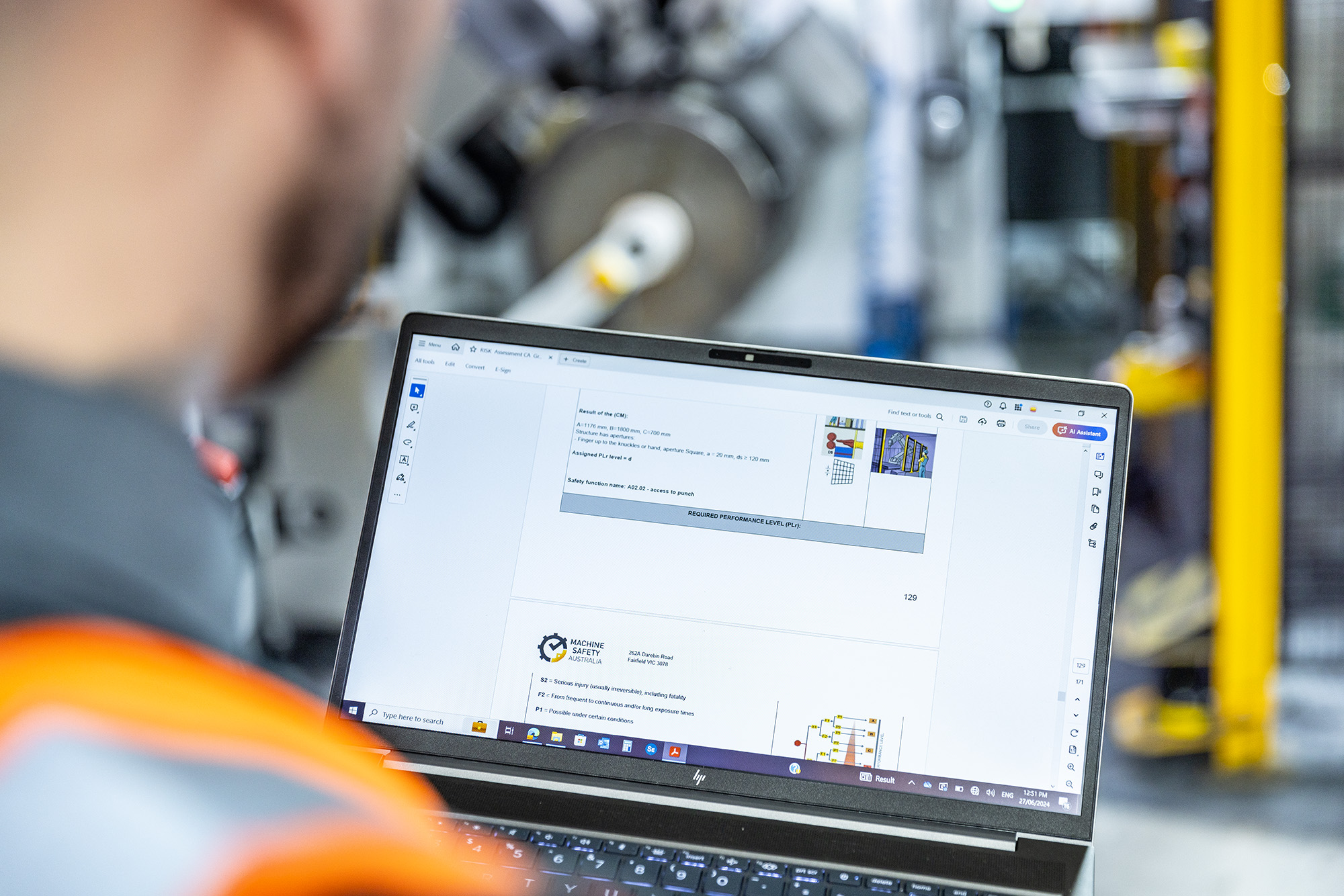

Utilising information from the Safety Functional Requirements document, the system is designed and verified to ensure that the achieved Performance Level meets the required PLr (Performance Level Required).

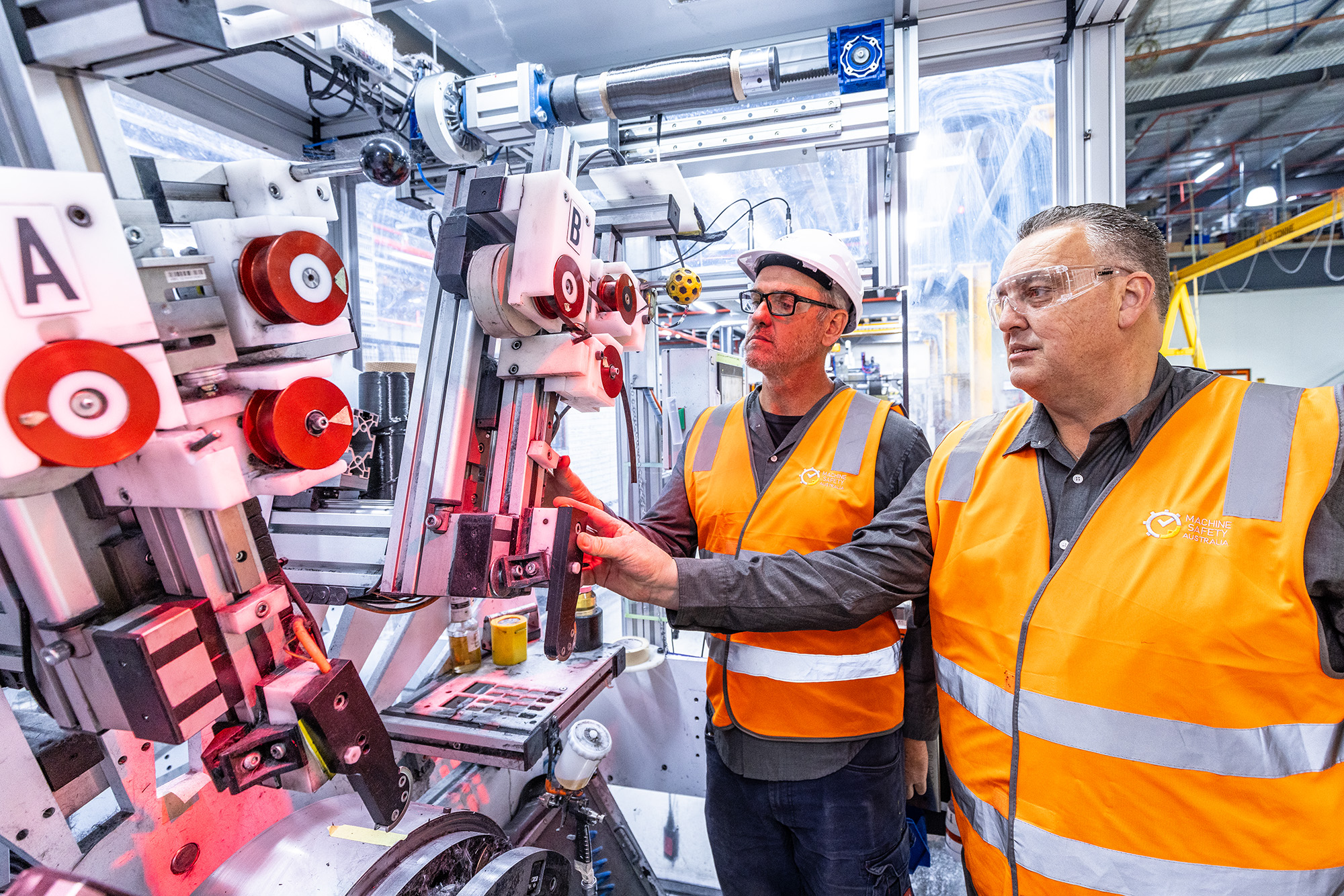

The system is installed, and each safety function is validated to ensure proper installation and correct functionality.

Ongoing maintenance and continuous improvement.

The point of using Lorem Ipsum is that it has more-or-less packages normal point of using.