Our dedication to continuous machine safety improvement means we are always seeking new ways to enhance the safety and efficiency of your machine operations.With that in mind, MSA offers you a comprehensive machine safety software design that integrates effortlessly with your current systems.

Our software solutions provide advanced monitoring, control, and automation capabilities to significantly enhance both machine safety and productivity. By implementing our advanced safety software, you can ensure that your machinery operates at peak efficiency while maintaining the highest safety standards. Our commitment to machine safety and innovation helps your business to protect its employees, reduce operational risks, and achieve greater overall performance.

Innovation is the core of our approach. When designing your machine safety software, we make sure technologies such as IoT, machine learning, and predictive analysis are utilised to develop a software solution modified to the operation of your industrial machinery.

Our safety software are designed to not only meet but exceed industry standards, ensuring that your operations are safe and efficient in the long run.

With modern machines becoming more complex, so do the risks associated with its operation.

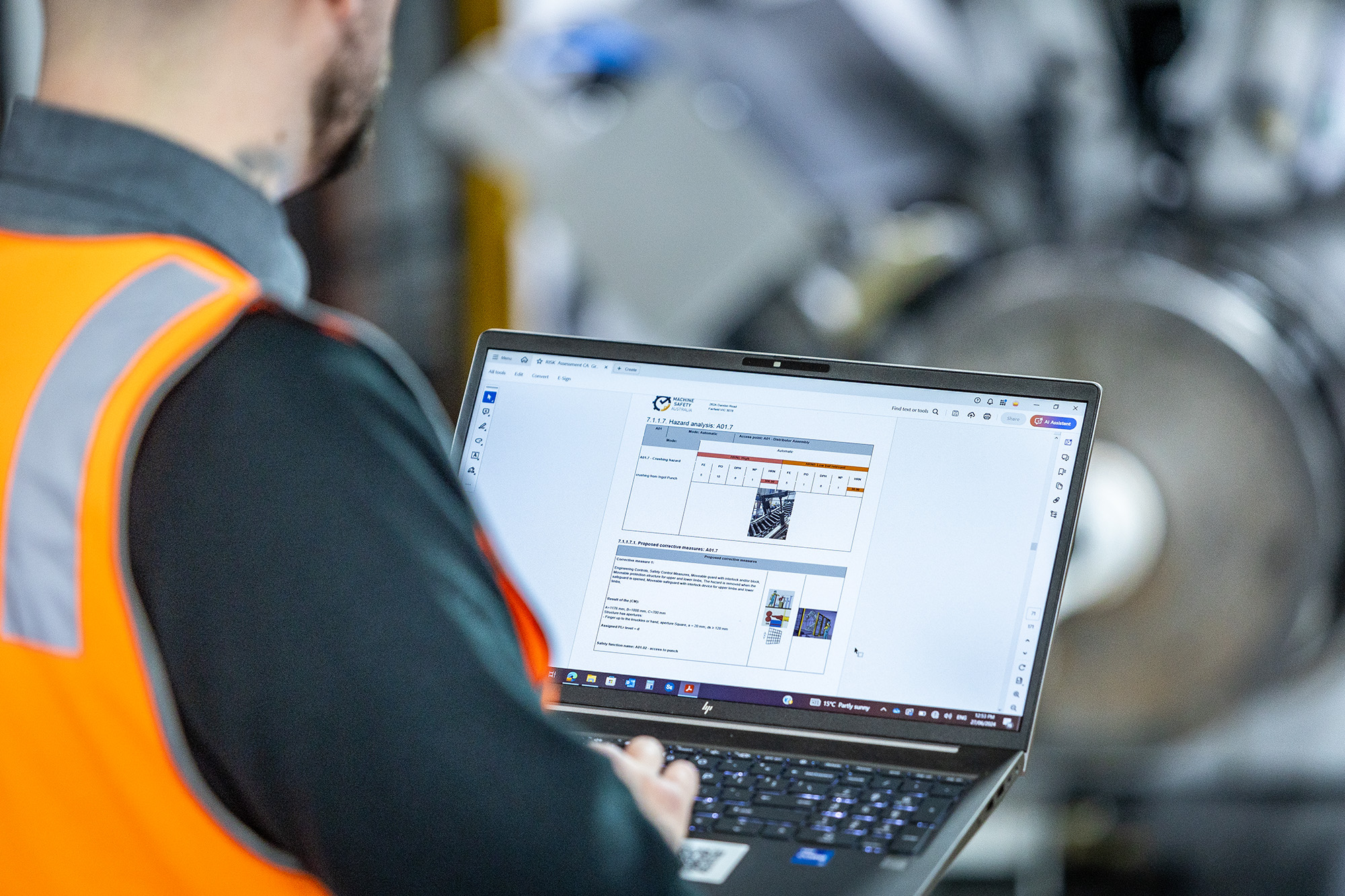

Machine Safety Assurance (MSA) offers you an insightful preview of the benefits you can expect when investing in our advanced machine safety software design.

We provide advanced monitoring features for your machine's hardware, enabling real-time checking of machinery operations and allowing you for quick responses to potential issues.

Our software includes predictive maintenance capabilities that identify potential failures before they occur and reduce unplanned machine downtime.

By automating safety checks and controls, our safety software improves the overall operational efficiency and productivity of your machines.

We design our machine safety software with the goal of being able to provide your business valuable data and analytics, helping you make informed decisions to optimise business performance.

With years of experience in the industry, Machine Safety Australia brings unparalleled expertise to the design and implementation of machine safety software design. Our team of certified safety professionals is dedicated to staying at the forefront of the industry by continually updating our knowledge of the latest safety standards, technologies, and best practices.

We adhere to the highest safety benchmarks worldwide, including international standards such as ISO 13849, IEC 62061, and OSHA guidelines. This commitment ensures that our software solutions provide the utmost protection, reliability, and compliance, giving you peace of mind that your machine operations meet global safety requirements.