Maintaining high machine safety standards is not just a regulatory requirement but an integral part of operational efficiency and worker protection. Machine Safety Australia offers a comprehensive safety verification service designed to ensure that all safety-related parts of control systems and safety functions in your machinery perform as intended, meet specified requirements, and comply with AS /NZS 4024.1 2019, Safety of Machinery Standards.

Our verification service is for businesses aiming to mitigate risks, enhance operational reliability, and ensure long-term compliance with safety regulations.

We adopt an integrated approach to Machine Safety Verification, ensuring that every aspect of your machinery’s safety is comprehensively assessed and optimised. Our verification process doesn’t just focus on individual components but examines the entire system to ensure seamless integration and optimal performance.

We evaluate the interactions between different safety functions and how they collectively contribute to reducing risks.

Our verification checkpoints include environmental factors, human-machine interactions, and operational workflows to ensure that all potential hazards are identified. This thorough approach not only ensures machine safety compliance but also enhances your machinery’s overall reliability and efficiency, providing a safer and more productive work environment. Our verification process ensures that every machine function is addressed, offering you confidence in your machine safety systems.

Investing in Machine Safety Verification offers a multitude of benefits that extend beyond compliance:

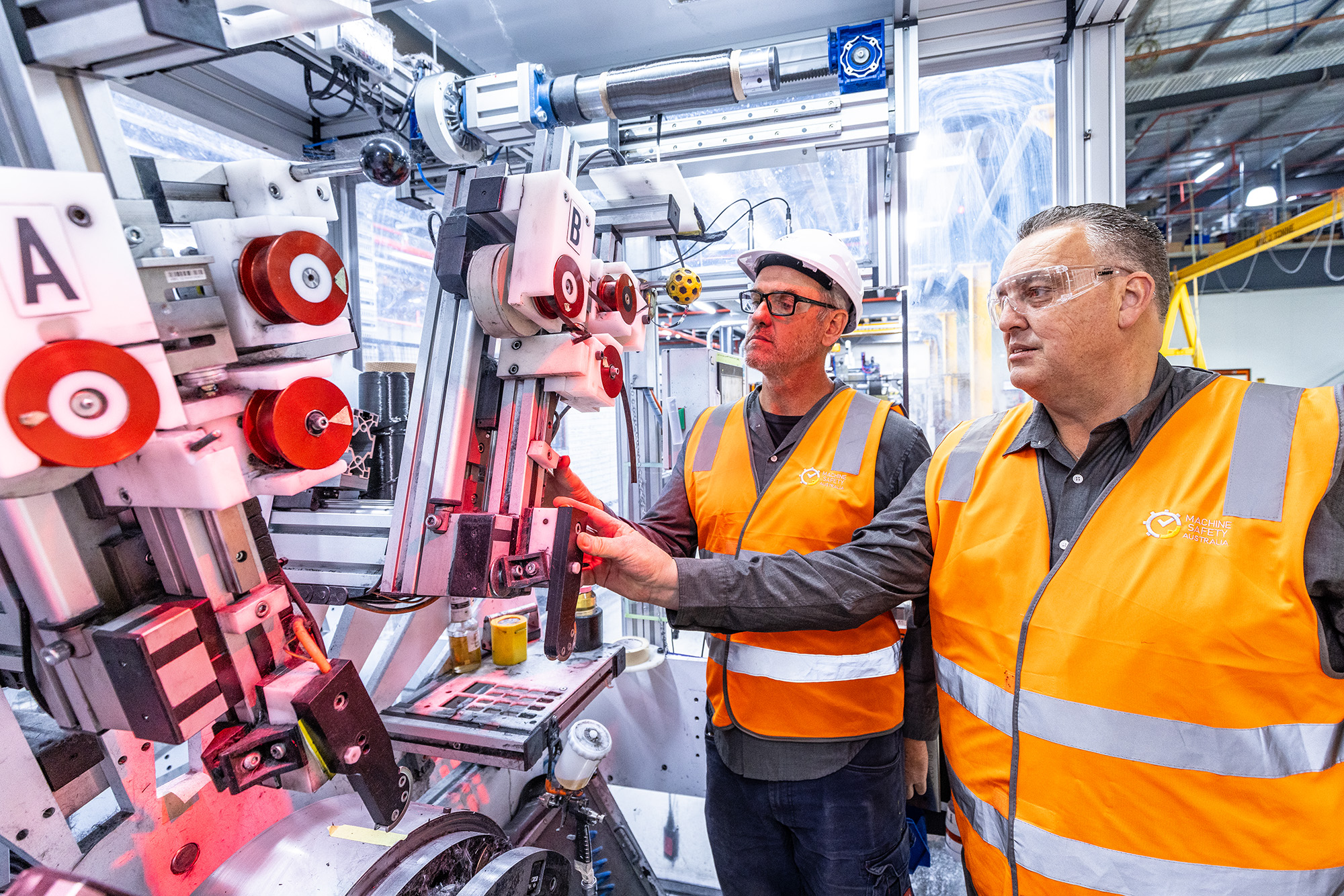

Our safety engineers are certified in the latest safety standards and regulations. They have extensive experience conducting risk assessments, designing safety systems, and performing detailed safety verifications.

Our technicians have hands-on experience with a wide range of machinery and industrial equipment. They are skilled in installing, validating, and maintaining safety systems, ensuring that every component functions correctly and reliably.

MSA's project managers oversee the entire verification process, from initial consultation to final verification. They ensure that all activities are completed on time and within budget, coordinating with your team to minimise disruptions to your operations.

Our data analysts utilise advanced analytics tools to monitor and evaluate the performance of your safety systems. By analysing data from various sources, they can identify potential issues and recommend proactive measures to enhance safety and efficiency.

Our training specialists provides education and support to your team, ensuring they are well-equipped to manage and maintain machine safety measures. They offer customised training programs that cover everything from basic safety principles to advanced system operations.